Hi-DEN

Hi-DEN (High Density Energy Network) addressed the challenge of Hydrogen storage capacity for fuel cell electric vehicles (FCEVs) and the resultant limits on vehicle range imposed by current solutions.

Project Overview

Hi-DEN (High Density Energy Network) addressed the challenge of Hydrogen storage capacity for fuel cell electric vehicles (FCEVs) and the resultant limits on vehicle range imposed by current solutions. Hi-DEN was a follow on to a successful NVN feasibility study on a novel high density, volumetrically efficient array of mini vessels approach to H2 storage tanks, which make much better use of package space than traditional composite overwound pressure vessels (COPVs) and improve volumetric efficiency and hence vehicle range by up to 50%. The aim of the project was to build and test a prototype vessel to prove the technology.

Project Overview

Hi-DEN (High Density Energy Network) addressed the challenge of Hydrogen storage capacity for fuel cell electric vehicles (FCEVs) and the resultant limits on vehicle range imposed by current solutions. Hi-DEN was a follow on to a successful NVN feasibility study on a novel high density, volumetrically efficient array of mini vessels approach to H2 storage tanks, which make much better use of package space than traditional composite overwound pressure vessels (COPVs) and improve volumetric efficiency and hence vehicle range by up to 50%. The aim of the project was to build and test a prototype vessel to prove the technology.

Technology Developed

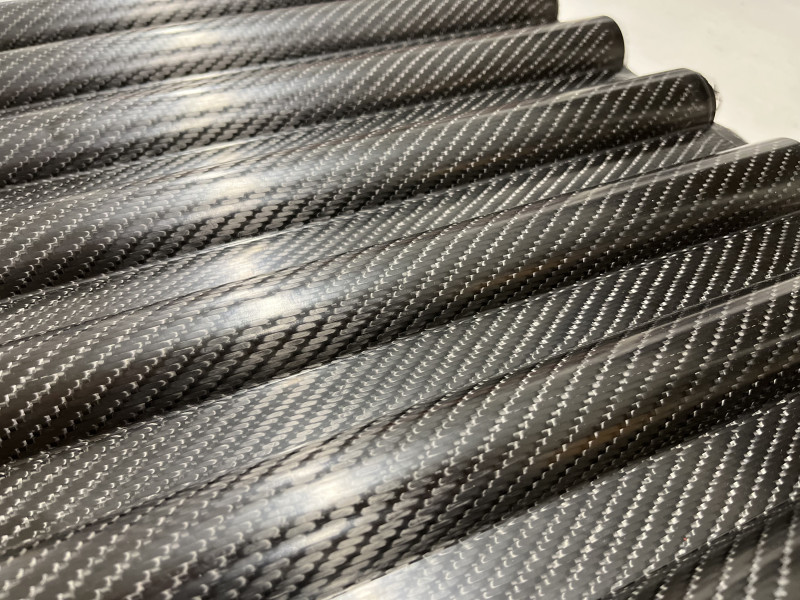

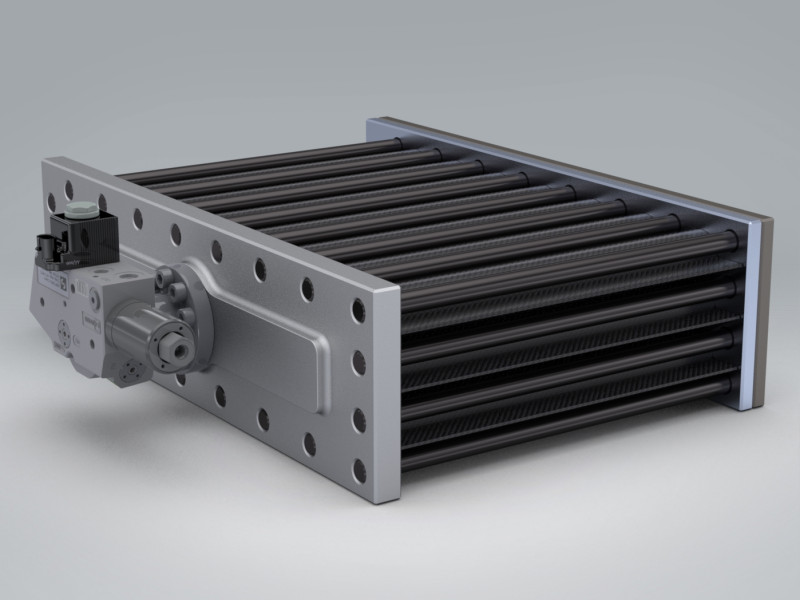

Carbon ThreeSixty developed the innovative tank design and manufacturing concept which stacks arrays of smaller vessels in a configurable manner with a scalable process to take full advantage of package space and allow complex shaped tanks to be produced. Antich & Sons developed the 3D woven carbon fibre arrays which enable the concept and can lay-down fibre at much higher rates than traditional tank winding. Viritech developed the HSCU (Hydrogen storage control unit) which can monitor up to 20 temperature locations in the tank and integrates fill control and leak detection. The next steps are scale up and on-vehicle testing.

Significant Project Outcomes

The project demonstrated the viability of the materials and the concept to achieve significant increases in volumetric efficiency, showing a 27% improvement based on the package space of a typical sub-floor battery compartment space for a family passenger vehicle. The manufacturing approach has been proven to be both feasible and scalable and the design enables integration in a standard approach. The project intends to continue development in follow on R&D and commercial projects.

Future Commercial Opportunities

The project has already generated commercial enquiries from both performance car OEMs and commercial HGV integrators who are struggling with H2 capacity in their available package space, with tank concepts developed to suit the available space. Funding opportunities are being investigated to progress the technology and production readiness further and to allow more work to be done on the testing and certification process.

NVN Funding

NVN funding has been crucial to get an innovative concept off the ground and into a concrete design and subsequent prototype. This has allowed a collection of SMEs to progress a technology that they would struggle to move forward without external support. The support from NVN has ultimately helped us to now be certain that H2 storage capacity is a real problem and that the Hi-DEN solution is needed by the market.